Choosing 4 m vs 5 m – plan efficiently

With the right length you reduce offcuts and butt joints, saving time and material. 4 m boards suit compact layouts; 5 m boards minimise joints on longer spans. Mixed lengths enable a calm laying pattern – depending on layout, substructure spacing and desired look.

Minimise offcuts & number of joints

Plan board lengths along the maximum span and trim only in edge zones. 4 m often fit project lengths around 3.8–4.0 m; 5 m are ideal if you want to avoid joints or make a light trim at 4.6–5.0 m. For lengths > 5 m, two 5 m runs clearly reduce the number of joints compared with two 4 m runs.

Guidance (simplified examples):

- Terrace length 3.9 m → choose 4 m, minimal trim

- Terrace length 4.8 m → choose 5 m, edge trim

- Terrace length 9.8 m → two 5 m runs with a planned butt joint

Mixed lengths (4 m/5 m) help lower offcuts and distribute joints symmetrically.

Handling, appearance, substructure

5 m boards are heavier and need more people and stable support for transport and alignment. Fewer butt joints create a calm look; planned joints on double joists appear technically clean. Consider material-dependent length changes (timber: swell/shrink; WPC/BPC: thermal expansion) and align butt joints always according to the manufacturer’s instructions.

Materials at a glance

Our range includes robust hardwoods, low-maintenance solid WPC boards, co-extruded solid boards (Autentica) and solid BPC boards. 4 m lengths are available; depending on variant, 5 m options are possible. The compact overview below helps your selection.

Timber: Bangkirai, Cumaru, Garapa – profiles & properties

Bangkirai, Cumaru and Garapa offer high density, a natural look and durable deck surfaces. Profiles range from grooved/ribbed to smooth on both sides. Untreated hardwoods weather to a uniform grey; oiled surfaces emphasise the colour and make regular care planning easier.

For calm patterns, 4 m and 5 m lengths give flexible grids. Cumaru tends to be darker and very resilient, Garapa lighter and even, Bangkirai balanced. Choose the profile for slip comfort, water runoff and feel – matching use and surroundings.

- Use: heavy wear, natural appearance

- Profiles: smooth, grooved/ribbed

- Care: oiling at sensible intervals

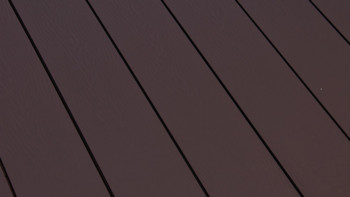

WPC solid & co-extruded (Autentica) – structure, cap, care

Solid WPC boards are full-profile and dimensionally stable. Depending on embossing, the surface is slip-resistant and barefoot-friendly. Co-extruded solid boards (Autentica) have an all-round 360° cap that further protects against stains and moisture.

Colour stability and care effort depend on colour, embossing and cap layer. Expansion is material-typical: plan sufficient gaps and follow maker guidance. Some variants are PVC-free – an option for more sustainable projects.

- Advantages: low maintenance, stable, barefoot-friendly

- Cap: co-extruded for increased stain resistance

- Note: expansion gaps per manufacturer

BPC solid (SlimDeck) – applications & feel

BPC boards combine bamboo fibre with polymer for a dense, slip-resistant surface. The slim SlimDeck format allows precise work and suits modern, calm patterns. The barefoot comfort convinces especially on seating and walking zones.

Available in 4 m with smooth or textured surfaces, BPC supports an even look. They are regarded as low-maintenance and – per product note – recyclable. Match colour and texture to façade, balustrade and furniture.

- Impression: modern, homogeneous

- Surface: smooth or textured

- Care: low effort, regular cleaning

Selection guide by use & location

Choose material and surface by load, barefoot zones and weather. Timber gives natural feel with possible greying; WPC/BPC offers stable calmness and low upkeep. Co-ex caps lower stain sensitivity – ideal by dining areas or grills with frequent use.

Barefoot comfort, slip resistance, surfaces

Barefoot areas benefit from fine-embossed, brushed or smooth profiles with a pleasant touch. Light embossing increases grip without being sharp. In splash zones, a textured surface is recommended; longitudinal grooves support drainage with fall.

For shaded aspects or north-facing decks, easy-care surfaces help as moisture lingers longer. Choose profiles that simplify cleaning and don’t trap dirt in deep grooves. Always follow maker-specific care/cleaning guidance to preserve look and function.

Loads, care intervals, colour development

In high-traffic zones, co-extruded solid boards score with all-round cap and higher stain resistance. Solid WPC/BPC profiles are robust and true to size; regular sweeping and washing usually suffice. With timber, oil quality, UV and use set the intervals.

Timber develops a natural patina up to greying, which many choose deliberately. For more colour-stable surfaces, use pigmented oils and review intervals seasonally. Accessories such as felt pads further protect surfaces.

Laying by length & material

Gap/expansion distances & clips – follow maker guidance

Plan gaps so length changes are taken up safely. WPC/BPC expands with temperature; hardwood works with moisture. Hidden clips ensure defined joints and a clean look. Butt joints belong on double joists; decouple abutting ends.

Align cuts and gap widths with laying temperature. Wall and edge clearances keep components free and prevent stress. Manufacturer instructions are binding; use start/end clips, intermediate clips and matching system screws

Indicative values (no guarantee; depends on maker/temperature):

- - WPC/BPC longitudinal gap: ~ 5 mm; edge clearance: ≥ 10–15 mm

- - Bangkirai/Cumaru/Garapa gap: ~3–5 mm; edge clearance: ≥ 10 mm

- - Butt joint on double joists; even gaps via spacers

Substructure & fall

A load-bearing, level build-up underpins look and durability. For WPC/co-ex, an aluminium substructure is recommended for dimensional stability; for hardwood, suitable timber joists are possible if spacing, drainage and separation layers are correct. Observe system joist centres.

Plan a fall of about 2% away from the building for reliable runoff. Localised levelling pads, isolation strips and adjustable pedestals ease set-up and limit standing water. Keep underside ventilation clear; a weed membrane and stable base reduce maintenance and settlement.

Price factors at a glance

Prices stem from material, length and execution – plus accessories and logistics. 4 m/5 m boards differ by offcuts, handling and profile. Co-ex caps raise material input yet offer tangible surface protection. Actual amounts vary by variant and current shop price.

Length, profile, cap layer, origin, accessories

The factors below influence the overall budget – from board length and profile to accessories and logistics. Depending on execution, material need, offcuts, install effort and carrier costs vary and can notably affect your budget.

- Length & format: 4 m/5 m, solid profile; cutting influences offcuts and quantities.

- Profile & surface: smooth, grooved/ribbed, embossed; feel and slip comfort differ.

- Co-ex cap layer: full 360° (Autentica) for higher stain resistance.

- Species & grading: Bangkirai, Cumaru, Garapa; density, look and care differ.

- Accessories & substructure: clips, spacers, joists (e.g. aluminium for WPC/co-ex); fall build-up.

- Logistics: long-goods carrier delivery; slots and access realistically affect total cost.

Our services: from samples to delivery

Our services support you from material testing to on-time delivery – discreet and needs-based. Order free samples to check colour, feel and embossing in daylight. Our expert advice via WhatsApp, phone or email helps with length choice, profile and accessories. We schedule preferred-date delivery with you; optionally storage³ (from a certain order value) until the agreed call-off. All options depend on stock; concrete options appear in basket and checkout.

Ready to get started?

Have samples sent and clarify questions with our expert team. Need another length? We’ve bundled all variants and lengths here: Decking boards