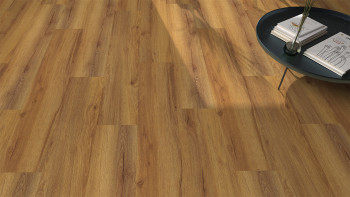

p>If you want to live in an ecologically sustainable and healthy way, organic flooring can be part of your strategy. Our organic floors are produced sustainably and are easy to install. They are pleasant to walk on, resilient, warm to the foot and can cope with what everyday life throws at them.

What is organic flooring?

Organic flooring is resilient flooring made from renewable raw materials. Generally, the material for organic floors should be processed as little as possible and should not contain harmful plasticisers. The certified organic floors from our range meet these requirements, particularly being free from PVC.

What properties should an organic floor covering have?

An ecological floor covering must first and foremost have been produced in a sustainable way. It should also be quiet, warm underfoot, hygienic, odourless, easy to clean, durable as well as easy to install.

Awards and certifications for organic vinyl

Organic vinyl flooring should be certified as such. The Blue Angel is one such seal that examines environmentally friendly products and awards them after careful testing. For example, no chemical pesticides must be used that can cause skin diseases, respiratory problems or even cancer.

The PEFC (Programme for the Endorsement of Forest Certification Schemes) is a programme of forest certification schemes that focuses on sustainable forest management. These independent seals help consumers choose sustainable, environmentally friendly products.

In our online shop, we offer you Meister design flooring and organic floors from the wineo brand that are safe for you and the environment. These products have been recognised with the Blue Angel and PEFC seal for sustainability for their environmentally conscious production and sustainability.

This is how easy it is to install organic flooring

Our ecological floor coverings are not only healthy and sustainable but are also easy to install using adhesive or the simple click system. In this respect, organic vinyl flooring is similar to our other high-quality floor coverings.

Are you interested? Take a look at our extensive range of organic flooring products. Feel free to order free samples to take home and see for yourself the first-class, robust and ecologically sound quality of the organic floors in our online shop. If you have any questions, our knowledgeable customer service centre will be happy to help you - please contact us!